This content has been automatically translated from Ukrainian.

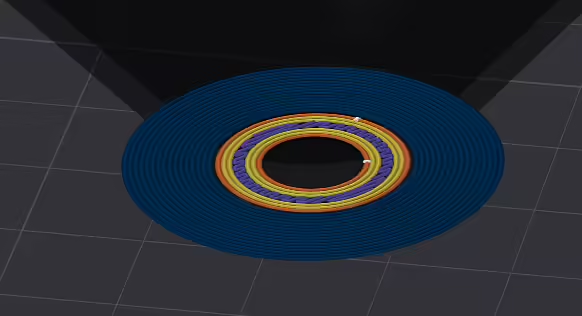

If you are into 3D printing, you have definitely heard of G-code. It is a set of commands that control the printer's operation: where to move, how fast, how much material to extrude, what temperature to maintain, etc.

How is G-code related to slicers?

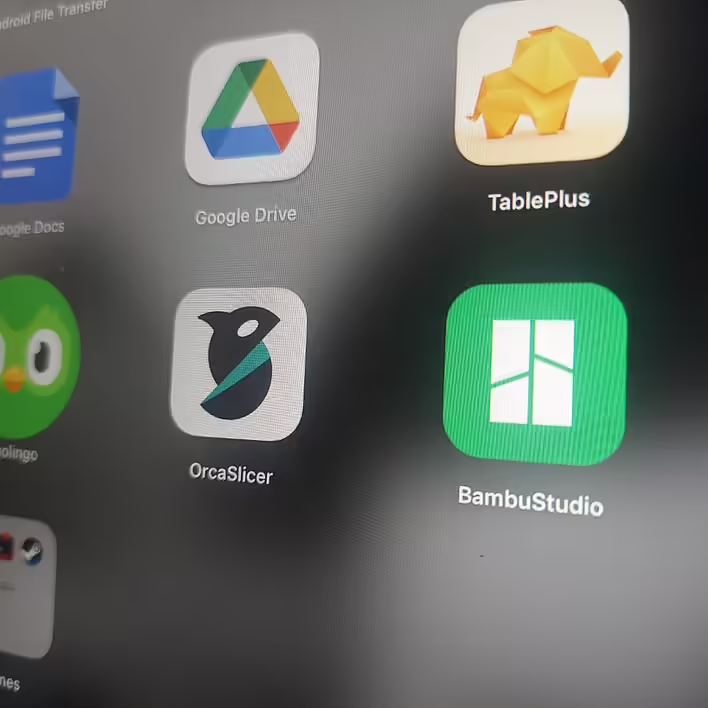

When you upload a 3D model to the slicer (for example, Cura, PrusaSlicer, Bambu Studio), it slices it into layers and creates step-by-step instructions for the printer. These instructions are what gets recorded in G-code.

For example, typical commands might look like this:

- G1 X50 Y20 E5 – move to coordinates (50,20) and extrude 5 mm of plastic

- M104 S200 – heat the nozzle to 200°C

- M140 S60 – heat the bed to 60°C

G-code can be viewed, edited manually, or even written from scratch if fine-tuning of the print is needed. But usually, the slicer does everything automatically.

You upload a 3D model, and the slicer "slices" the model into G-code so that the printer understands what to do.

This post doesn't have any additions from the author yet.