Table of contentsClick link to navigate to the desired location

This content has been automatically translated from Ukrainian.

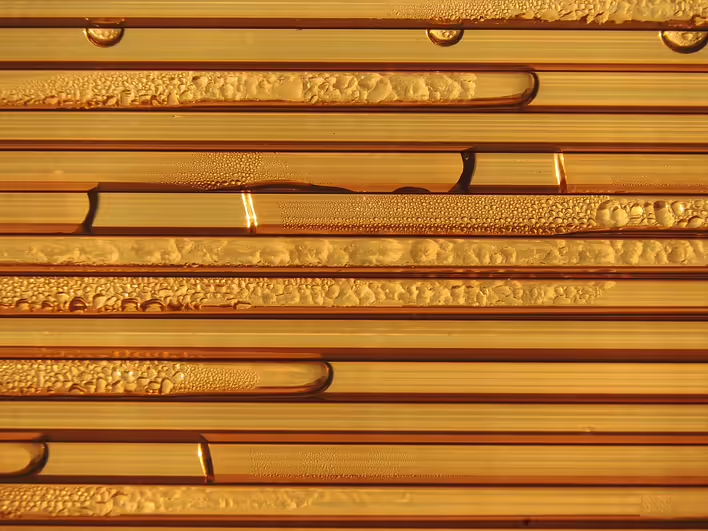

Cellular polycarbonate is a modern building material that is ideal for creating greenhouses, canopies, conservatories, and other transparent structures. Its popularity is due to its lightness, strength, high light transmission, and ability to retain heat. However, to ensure that the structure lasts long and effectively performs its functions, it is important to choose the material correctly. We will tell you what to pay attention to in order to buy cellular polycarbonate of the best quality.

Optimal thickness – a key factor

The thickness of cellular polycarbonate is one of the main parameters that affects its strength, thermal insulation characteristics, and service life. Here are the main recommendations:

- 4-6 mm – ideal for greenhouses and hotbeds. It transmits light well and retains heat, providing a favorable microclimate for plants, but it can bend under strong wind or snow.

- 8-10 mm – suitable for canopies, awnings, and gazebos. It withstands wind, hail, and even a small layer of snow.

- 12-16 mm and more – optimal for conservatories, winter gardens, and parking lot roofs. It provides excellent thermal insulation and withstands significant loads.

Material quality: what to pay attention to?

Not all polycarbonate is the same. On the market, you can find products of varying quality, and it is important to know how to distinguish reliable material from low-grade ones.

- Density. Quality polycarbonate has a density of at least 0.7-0.8 kg/m². Sheets that are too light may be brittle and break easily.

- Presence of UV protection. Sunlight gradually destroys the structure of polycarbonate, so it is important to choose sheets with a UV protective layer. It prevents yellowing, loss of transparency, and brittleness of the material. It is better if the protective layer is applied by extrusion rather than as a regular film.

- Number of layers. The more chambers (layers) in cellular polycarbonate, the better its thermal insulation properties.

Choosing a color: does it matter?

Yes, it certainly does! The color of polycarbonate affects how it transmits light and heat.

- Transparent (colorless) – provides maximum light transmission (up to 85%) and is best suited for greenhouses.

- Bronze or smoky – a good option for canopies and gazebos, as it provides pleasant shade and protects against overheating.

- Milk (opal) – ideal for terraces and awnings, as it diffuses light and creates soft illumination.

- Green, blue, yellow – used less frequently, more for decorative structures.

How to check quality before purchase?

Before making a final decision, conduct a few simple checks:

- Try bending the sheet. Good material is flexible but does not break.

- Check the weight. A sheet that is too light may indicate savings on materials.

- Look at the labeling. Quality polycarbonate should indicate thickness, manufacturer, and presence of UV protection.

- Ask about the warranty. Reliable suppliers, including the polycarbonate store Sotex Trade, offer certified products from the manufacturer. If you are offered very cheap polycarbonate with a warranty of 1-2 years, it is worth considering its quality.

The right choice of polycarbonate is the key to the durability of your greenhouse, canopy, or conservatory.

This post doesn't have any additions from the author yet.