![Post cover: [P1S] On-screen message - Z-axis lead screw needs lubrication](https://tseivo-prod.s3.eu-north-1.amazonaws.com/n2484aszggdtb76vwovcelpt4vag)

This content has been automatically translated from Ukrainian.

I already wrote about the first maintenance of the P1S printer. Almost a month into the job, I saw a message on the screen, "Z-axis lead screw needs lubrication".

If yours Bambu Lab P1S showed such a message, it means that the screw (or all 3 screws) of the axis Z (the one that raises and lowers the platform) needs care. Without lubrication, it can work noisily, with increased wear and even cause errors during printing.

What is needed:

- Grease (for example, Super Lube or similar, without aggressive solvents). The printer comes with several Grease sticks, then use it for the first time. Then you need to buy a Super Lube

- Lint-free napkin.

- Disposable glove (optional to avoid getting dirty).

Step-by-step instructions:

- Turn off the printer and wait for the platform to stop completely.

- Clean Screw Z from dust and old lubrication with a soft lint-free napkin. It will have to be thrown away.

- Apply a new lubricant - a few drops or a thin layer along the entire length of the thread. Do not smear as shown on YouTube - they then simply wipe and throw away a bunch of excess lubricant.

- Turn on the printer and through the menu or manually raise/lower the platform several times so that the lubricant is evenly distributed.

- Check the result <TAG1> platform movement should be smooth and without creaks.

Tip: lubricate the Z screw approximately every 200–300 hours of printing or when the appropriate message appears.

Here is a link to official bambulab documentation:

https://wiki.bambulab.com/en/general/lead-screws-lubrication

Well, I also described this step in the post about the first service.

This post doesn't have any additions from the author yet.

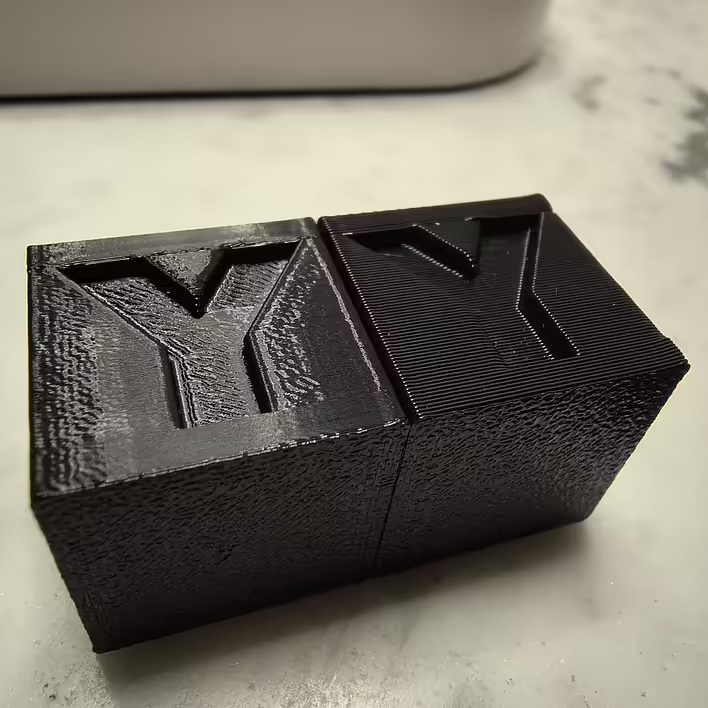

![[Що надрукувати] Витискач для тюбиків](https://tseivo-prod.s3.eu-north-1.amazonaws.com/1n2nj9awamp0cal358blvpihswju)

![[Print Army] The first 50kg of printed products for the army](https://tseivo-prod.s3.eu-north-1.amazonaws.com/ud1y2vcjnjrg51pw18ljubptwmgd)

![HMS error: 0300-0d00-0002-0001 what does it mean and how to fix it? [P1S]](https://tseivo-prod.s3.eu-north-1.amazonaws.com/0wi0y60gycmr9yktq6uss8vyao12)