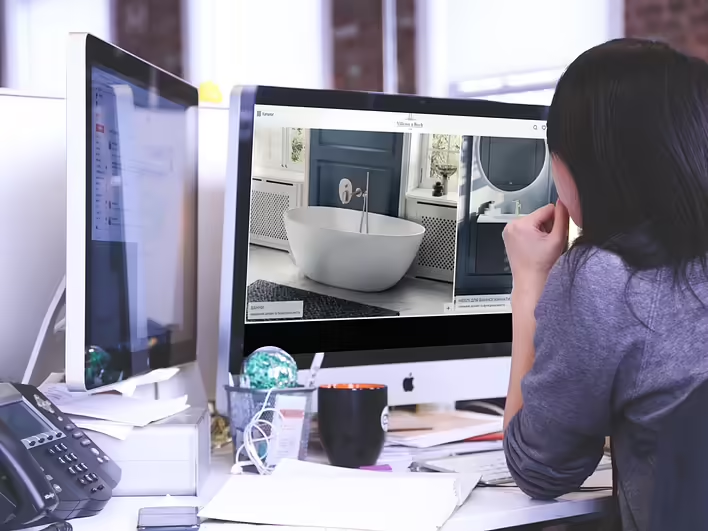

The main element of any bathroom is almost always a container designed for taking water procedures. Today, stores offer a wide range of such products, which come in the shape of an oval, semicircle, circle, triangle, pentagon, hexagon, etc. Usually, the length of baths made by well-known manufacturers is 1500, 1700, or 1800 millimeters.

The width reaches 700, 800, or 850 millimeters. The height is 650 millimeters. To enhance bathing comfort and promote well-being, baths are additionally equipped with massage systems, lighting, comfortable handles, soft headrests, comfortable armrests, and other types of accessories.

Materials for Bath Manufacturing

Cast Iron

Modern bathing containers are manufactured by domestic and foreign companies from cast iron sheets with a thickness of 5 millimeters. They stand reliably on a pre-prepared base. The water poured in does not make overly loud sounds, and the sufficiently thick walls retain thermal energy for a long time, while the enamel coating adheres securely to the surface. However, cast iron baths weigh about 120–130 kilograms and usually have a rectangular shape. The enameling process involves heating the cast iron to 1250 degrees, which causes the formation of pores that become contaminated.

Steel

The manufacturing of bathing tubs involves welding individual parts or pressing a solid steel sheet. Due to the good plasticity of the material, baths can take on various geometric shapes and sizes. The weight of such products is 4–5 times less than that of a cast iron bath. However, installed products must be securely fixed. The water collected cools quickly, and when poured, it makes loud sounds. This last problem can be solved by filling the external surfaces with mounting foam.

Acrylic

Sheets of artificial polymer are placed in a vacuum chamber, where they are heated and subjected to extrusion, allowing for the formation of products in the desired shape. The rigidity of the surfaces is improved by reinforcing the baths with additional layers. The weight of bathing containers reaches about 15–25 kilograms, and their structure, devoid of internal pores, slows down the decrease in water temperature to optimally warm. The flow of collected water falls silently, but heating to 160 degrees is accompanied by surface melting. Acrylic baths are also damaged by solvents, household chemicals, and sharp objects.

Quartz

The acrylic component is supplemented with quartz, which increases the strength of the product. Manufactured using casting technology, quartz baths Villeroy & Boch are free of air pores, take on various geometric shapes, and can resist the impact of sharp objects. However, the structure, when heated to temperatures of 160 degrees and above, begins to melt, leading to changes in the initial contours of the bath. Additionally, products of this type have a high price, which is unaffordable for most buyers.

This post doesn't have any additions from the author yet.

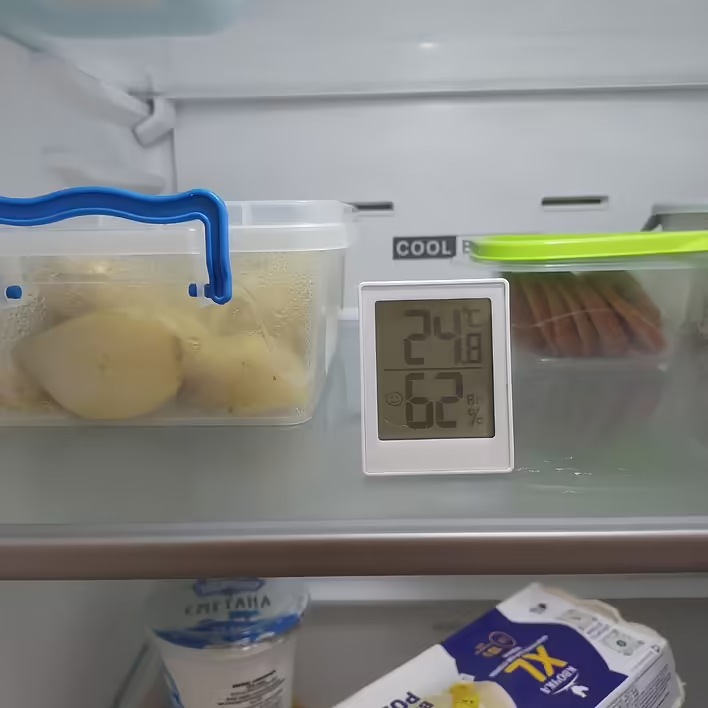

![[Personal Experience] Refrigerator and EcoFlow River 2 Pro](https://d3kb0xa9zqcv9v.cloudfront.net/1r0v5gpwhp1vxvrr9n27zjkb1hwu)

![[Personal Experience] Electric Kettle and EcoFlow River 2 Pro](https://d3kb0xa9zqcv9v.cloudfront.net/1pwkxgsba3505v6h0u1qzjo5izfw)